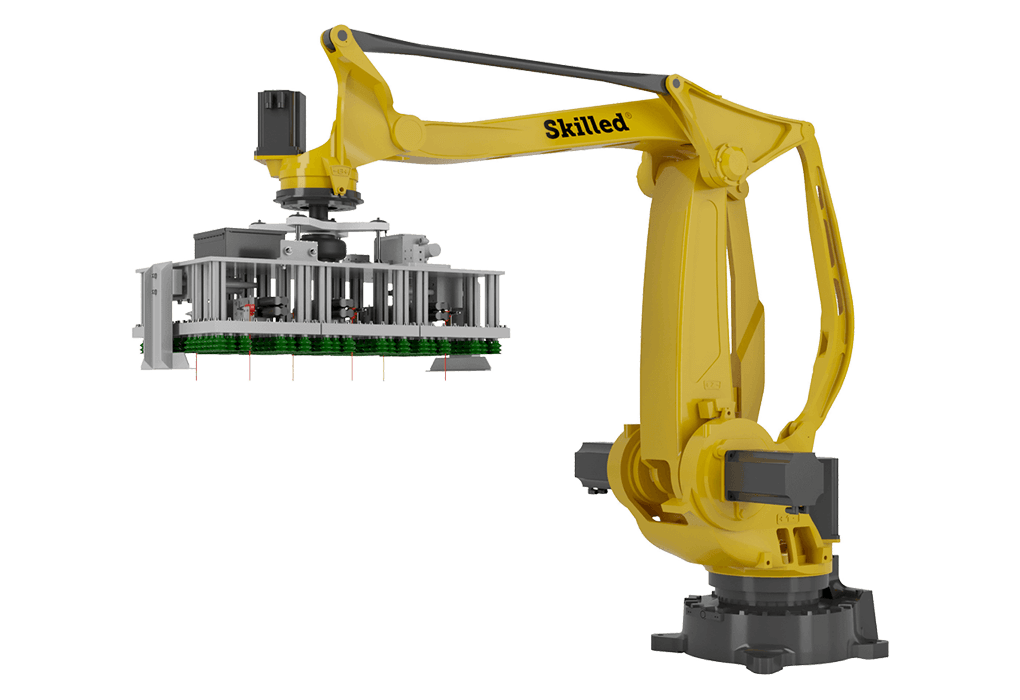

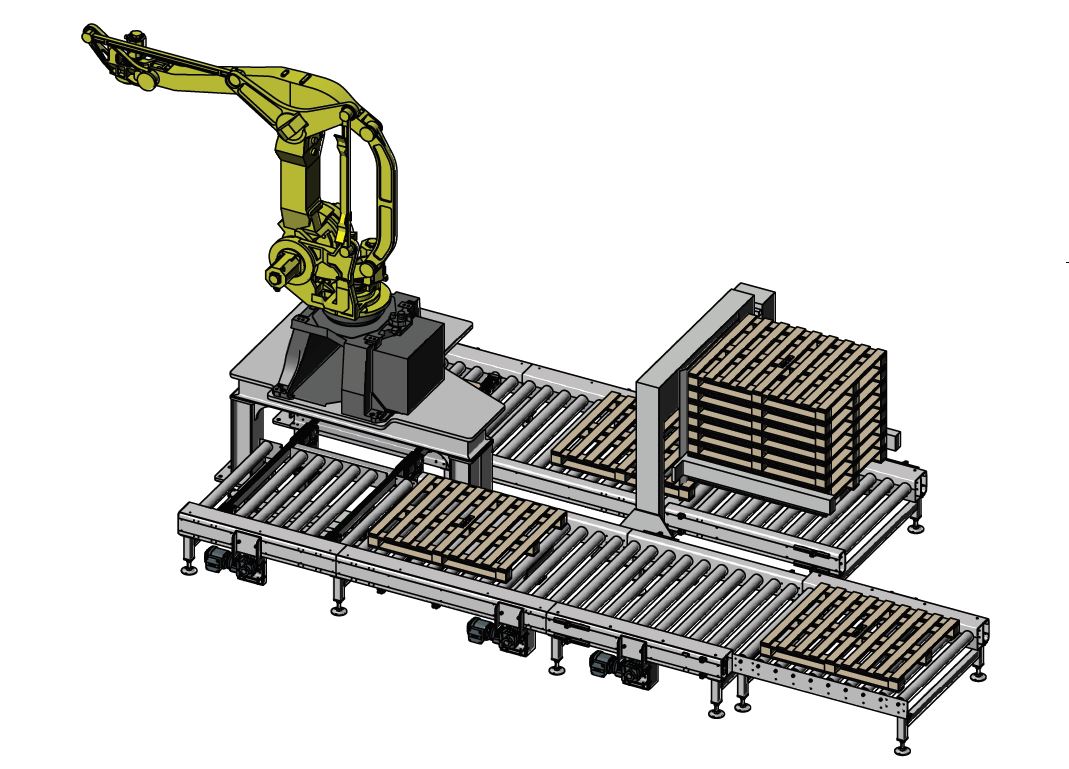

Robot Palletizer | Skilled 304 -603

Robot Palletizer | Skilled 304 Robot Palletizer | Skilled 603 Articulated robots are robot with rotary joints. Articulated robots can range from simple two-jointed structures to systems with 10 or more interacting joints. They are powered by a variety of means, including electric motors. An articulated robot, like the our Skilled 304 or 603, […]