Trigger Machine | MMM Trig

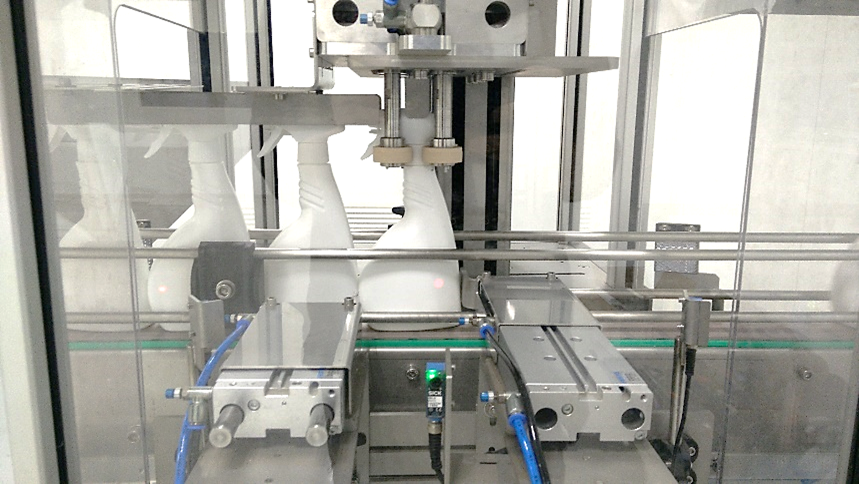

Trigger Machine | MMM Trig Trigger tightening machine of in-line model, designed for screw caps and trigger pumps. The purpose of the trigger sealer is to close packs, which are equipped with a spray pump (trigger pump), in an economically justified manner with an adjustable force and a high repetitive accuracy. The packages are manually […]