Trigger Machine | MMM Trig

Trigger Machine | MMM Trig

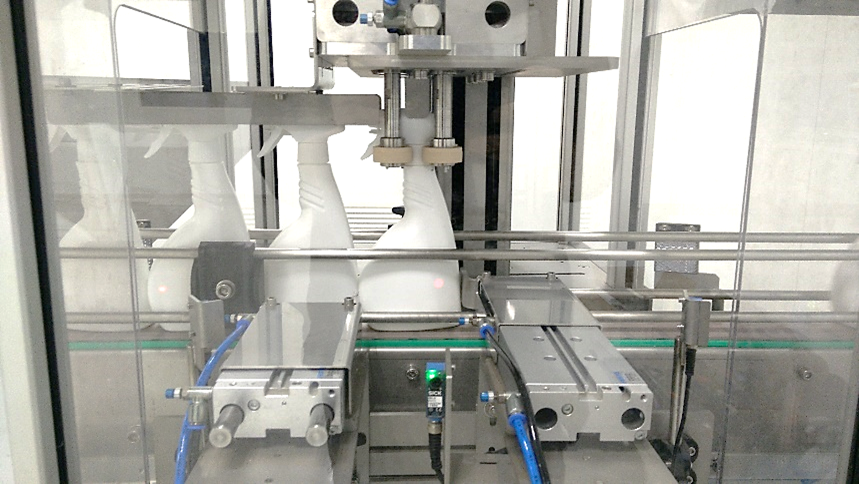

The purpose of the trigger sealer is to close packs, which are equipped with a spray pump (trigger pump), in an economically justified manner with an adjustable force and a high repetitive accuracy. The packages are manually fitted with the spray pump by an operator who places the spray pump in the package and lightly tightens the swivel on the package. The machine automatically takes care of the processing of the automatic packages.

- Very compact machine

- Ergonomic construction

- Working height of the machine adjustable between 920 and 980mm.

- Easily adjustable

- Closing height and diameter adjustable by means of a hand wheel in function of the bottle. Both are measured with a counter, therefore previous settings can be easily repeated.

- Adjustable tightening speed and force for better closure.

- Adjustable stop and stop cylinders attached to the machine.

- Equipped with top guide for alignment of the spray head with the package.

- Four tightening rollers for proper centering.

- Simple and intuitive operation and maintenance

- Simple control panel with touch screen)

- Worn drive rollers can be easily replaced.

- Minimal wear by monitoring the tightening torque, above which the motor stops.

- Frame constructed of 304 stainless steel and anodized aluminum.

- Maintenance-free electric torque motors, type BLDC.

- No format parts required.

- Automatic inlet and outlet control of packages and check for tightened cap.

- Safe machine

- Aluminum frame with polycarbonate shielding. All moving parts are located within this cabinet and are shielded from the operator.

- CAT. 2 system architecture, Performance level C.

- The machine conforms to the latest machine directives. Reference: 2006/42/EC

- Capacity

- 1200 closures per hour on average.

- Flexibly deployable

- Possibility of placing over different sizes of conveyor belts.

- Different sizes of bottles can be closed.

- Possibility of closing normal caps without a pump.

Physical dimensions

| Depth | 1020 mm (exclusive electrical cabinet) |

| Width | 1560 mm |

| Height | 1935 mm (exclusive signal beam) |

Een reactie achterlaten